Sohle Seo U Lokelang ho se Tseba ka Ente Molding

Ente Molding ke Eng?

Injection Molding ke mokhoa oa tlhahiso ea ho hlahisa likarolo ka bongata bo boholo. E sebelisoa haholo lits'ebetsong tsa tlhahiso e ngata moo karolo e tšoanang e ntseng e etsoa makhetlo a likete kapa a limilione ka ho latellana.

Ke li-polymer life tse sebelisoang ha ho etsoa ente?

Tafole e ka tlase e thathamisa tse ling tsa lisebelisoa tse sebelisoang hangata:

Acrylonitrile-Butadiene-Styrene ABS.

Nylon PA.

Polycarbonate PC.

Polypropylene PP.

Polystyrene GPPS.

Mokhoa oa ho etsa ente ke eng?

Mokhoa oa ho bopa ente ea polasetiki o hlahisa likarolo tse ngata tsa boleng bo phahameng ka ho nepahala ho hoholo, ka potlako haholo. Lisebelisoa tsa polasetiki ka mokhoa oa li-granules li qhibiliha ho fihlela li le bonolo hoo li ka kenngoa tlas'a khatello ea ho tlatsa hlobo. Phello ke hore sebopeho se kopitsoe hantle.

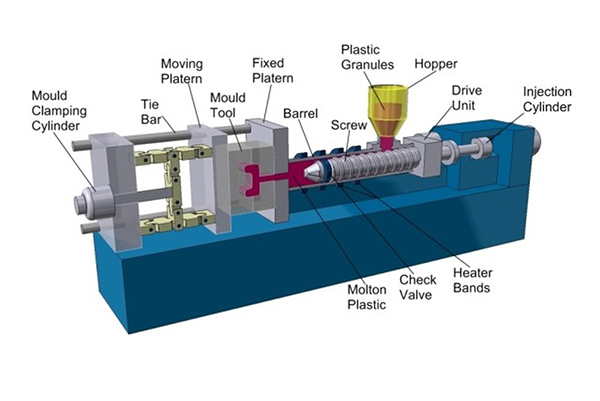

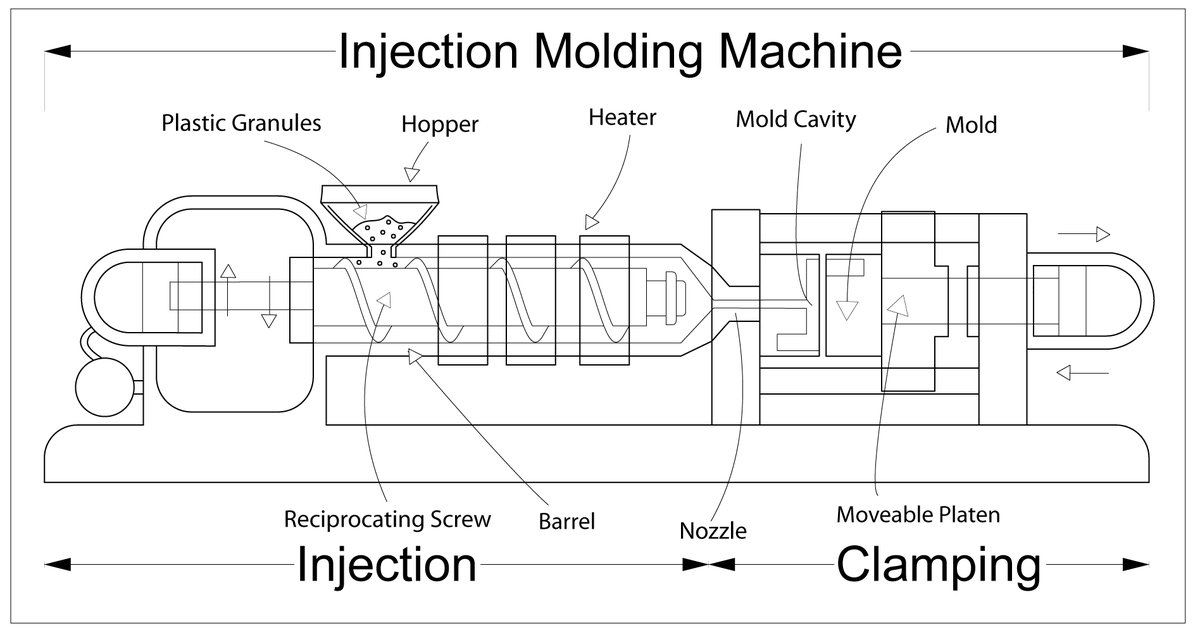

Mochini oa ho etsa ente ke eng?

Mochini oa ho etsa ente, kapa (mochini oa ho etsa ente ea BrE), o tsejoang hape e le mochini oa khatiso oa ente, ke mochini o etsang lihlahisoa tsa polasetiki ka mokhoa oa ho bopa ente. E na le likarolo tse peli tse kholo, yuniti ea ente le yuniti ea clamping.

Mechini ea ho etsa ente e sebetsa joang?

Li-granules tsa karolo li fepeloa ka hopper ka har'a barrel e futhumetseng, e qhibilihisitsoeng ho sebelisoa libanta tsa heater le ketso ea ho ferekanngoa ea sekoti se bilikang. Ka mor'a moo, polasetiki e kenngoa ka molomo ka har'a mokoti oa hlobo moo e pholileng ebe e thatafala ho ea ho sebopeho sa lesoba.

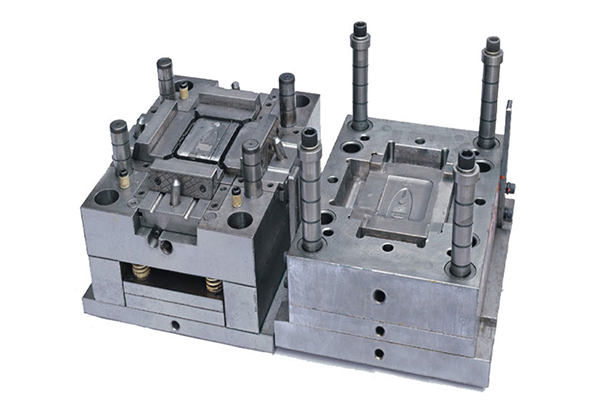

Tse ling tsa Litlhokomeliso Bakeng sa Mold ea Ente ke Life?

Pele u leka ho hlahisa karolo ka mokhoa oa ho enta, nahana ka lintlha tse 'maloa tse latelang:

1, Litlhahlobo tsa Lichelete

Litšenyehelo tsa ho Kena: Ho lokisa sehlahisoa bakeng sa tlhahiso e entsoeng ka ente ho hloka letsete le leholo la pele. Etsa bonnete ba hore u utloisisa ntlha ena ea bohlokoa esale pele.

2, Bongata ba Tlhahiso

Etsa qeto ea palo ea likarolo tse hlahisoang moo ho bōptjoa ha ente ho fetoha mokhoa o theko e boima ka ho fetisisa oa ho etsa

Etsa qeto ea palo ea likarolo tse hlahisoang tseo u lebeletseng ho senya le letsete la hau (nahana ka litšenyehelo tsa moralo, teko, tlhahiso, kopano, papatso le kabo hammoho le theko e lebelletsoeng ea thekiso). Haha moeling o tsitsitseng.

3, Mehopolo ea Moralo

Moralo oa Karolo: U batla ho rala karolo ho tloha ka letsatsi la pele ka ho bopa ente kelellong. Ho nolofatsa geometry le ho fokotsa palo ea likarolo pele ho nako ho tla lefa meputso ho theosa le tsela.

Moralo oa Sesebelisoa: Etsa bonnete ba hore o rala sesebelisoa sa hlobo ho thibela liphoso nakong ea tlhahiso. Bakeng sa lethathamo la liphoso tse 10 tse tloaelehileng tsa ho bopa ente le mokhoa oa ho li lokisa kapa ho li thibela bala mona. Nahana ka libaka tsa liheke 'me u tsamaise lipapiso u sebelisa software ea moldflow joalo ka Solidworks Plastics.

4, Maikutlo a Tlhahiso

Nako ea Cycle: Fokotsa nako ea potoloho ka hohle kamoo u ka khonang. Ho sebelisa mechine e nang le theknoloji ea ho matha ho tla thusa hammoho le lisebelisoa tse nahannoeng hantle. Liphetoho tse nyane li ka etsa phapang e kholo mme ho fokotsa metsotsoana e seng mekae ho tloha nakong ea potoloho ea hau ho ka fetolela ho boloka chelete e ngata ha u ntse u hlahisa likarolo tse limilione.

Kopano: Rala karolo ea hau ho fokotsa kopano. Boholo ba mabaka a etsang hore ente e etsoe ka boroa-bochabela ho Asia ke litšenyehelo tsa ho kopanya likarolo tse bonolo nakong ea ente.

Nako ea poso: Nov-05-2020